Design Manual Test Press Fixtures To Your Needs

Our manual test press fixtures are developed to be fully integrated test solutions that are ready for use as soon as they are received. You wont face Some assembly required or batteries not included when working with RTI to develop a test press solution.

Test presses consist of a standalone base that is sized to your application and a removable interface module that manages all electrical interconnects incorporated into the working solution and aligns the unit under test to the test points.

Checksums Turnkey Test Fixture And Program Services

CheckSum is the only automatic test equipment supplier that offers complete turnkey packages that are ready for production when the land on your receiving dock. This means you receive optimum performance and reliability at the lowest overall cost.

Not only is the price of Analyst systems a fraction of traditional ICT, more importantly, ongoing operating costs are typically 50% less.

Our focus on minimizing fixture cost and simplifying programming saves money each time a new test job comes on line. Electronic manufacturers who switchover to CheckSum systems find the cost savings to be immediate and dramatic.

In Circuit Test Fixtures and Fixture Kits

CheckSum pneumatic and mechanical test fixtures are rugged, reliable and inexpensive-especially when compared to the heavy vacuum fixtures required by traditional in circuit testers.

CheckSum fixturing is compatible with all of CheckSums test systems. Since the electronics are isolated from the fixture you can use CheckSums factory-built fixtures or build your own special fixturing or adapters that can accommodate ribbon-cable connectors.

Designing The Test Fixture

To start the design process, go to fixturfab.com and click Design Now. Create a new project and enter the name, PCB thickness, and upload the Eagle .brd file. You can find the Power Delivery Boards Eagle BRD file here. FixturFab supports Eagles .brd files, KiCADs .kicad_pcb files, Altium Test Point CSV reports, and gerbers from any other EDA software.

For this project select a DEV260 fixture. These are laser-cut for increased reliability and have a similar maximum PCBA size to our entry-level production fixture solutions.

The parsed test point information from the ECAD file will then be displayed. The PCB board width and height are automatically detected, but you should always verify that these values are correct.

Recommended Reading: How To Get Nail Polish Out Of Carpet

High Quality Fixture Kits

You can be sure that our all of our test fixtures are built to a high standard. Our partnership with the Everett Charles Technologies Test Fixture Group, the worlds leading manufacturer of PCB test fixtures, allows us to offer a best in class range of test fixture kits and customisation. And our longstanding experience in the field guarantees you a professional and knowledgeable service.

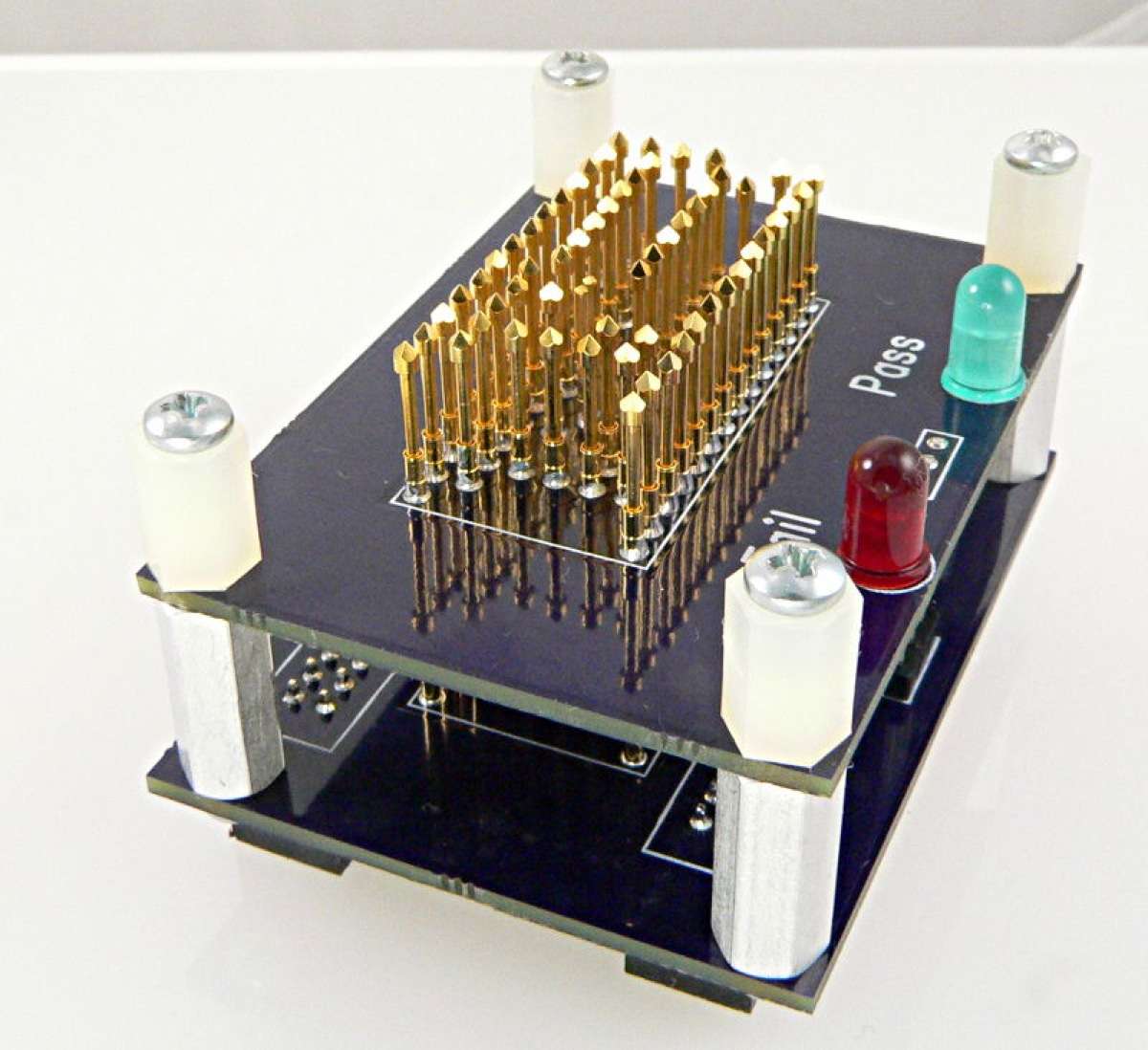

Quick Swap Interface Modules

We design and manufacture interchangeable interface modules to meet your UUT footprint and other criteria based on your test application. The bed of nails style interface module is a UUT-specific design that routes signals from your UUT out to other components in your test configuration or directly to connectors of choice. Interface modules and can be removed from the test press base quickly and easily. This adaptability allows for rapid product changeover in engineering and production test environments.

Also Check: How To Do Dip Powder Nails

Checksum Fixture Systems And Fixture Kits

Model 12KN Dual Level Long-Travel Pneumatic Fixture System

The 12KN Dual Level Pneumatic Fixture System is integrated into a rack-cabinet and designed to be the basis for CheckSum bed-of-nails test systems. The long-travel press eliminates the need to open and close a lid between tests. The fixture kits are easily changed by sliding the fixture top plate and base into place. The system uses a universal spring-probe fixture interface. The fixture system can accommodate up to 5200 test points and uses standard CheckSum fixture kits. Integrated into the system is rack space for system electronics and an operator keypad with a minimum selection of buttons to make it easy, safe, and error-free for the operator to use. The 12KN is compatible with existing CheckSum KIT1000-QC and KIT2KN-QC fixtures. A safety light curtain provides operator safety.

Fixture Guidelines: Assembly size can be up to 24 x 13.2 inches , dual level, single-sided and double-sided probing plus TestJet.

Model TR-7-1000-QC Pneumatic Fixture System

The TR-7-1000-QC is a new version of our popular TR-7-1000 pneumatic fixture receiver. Uses air pressure to press the assembly being tested onto spring probes. Usable to 1000 test system connections, the Model TR-7-1000-QC is ideal for most testing applications including dual-level fixturing. Using low-cost removable fixture kits, it can accommodate assemblies where adding a vacuum seal is difficult.

Model TR-5-400-QC Mechanical-Advantage Fixture System

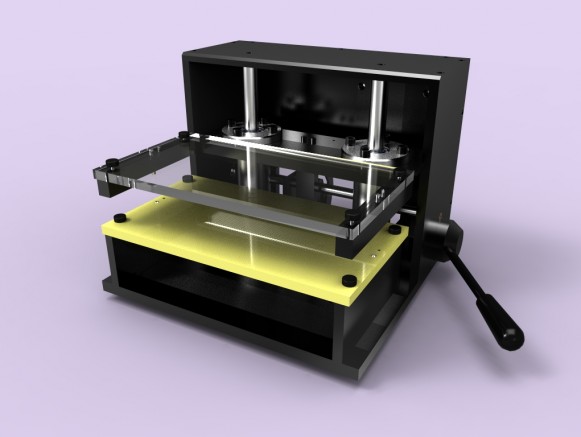

Mechanical Press Fixture Kits

For more than 20 years, Cortek Test Solutions has manufactured our premiere off-the-shelf Mechanical Press Fixture Kits in two standard sizes. Our Mechanical Presses offer the versatility to change out fixture plates which enables our customers to test multiple products on the same fixture kit. This flexibility makes it a cost-effective testing solution that also standardizes your test setup. Our Press Fixture Kits are designed to provide precise, bed-of-nails contact in both R & D and production environments.

Read Also: Can I Do My Own Gel Nails At Home

Common Test Press Bases

Test press bases use robust stainless steel and ball-bearing linear guides for smooth vertical compression. This ensures consistent, repeatable, and reliable test results while preventing damage to the UUT or test probes during use.

Smaller 750 series test presses utilize a combination of clamshell and vertical guide designs while larger 752 series test presses are fully vertical.

Open Position

The lid sits at a 50 angle when the press is in the open state, giving the operator ample room to load and unload UUT between test. The height of the interface module and length of standoffs on the lid impact this working area.

Resting Position

As the lever is pulled to close the lid, it first comes to rest in a horizontal position parallel to the baseplate. The standoffs installed on the lid sit above the UUT without making contact and the UUT does not engage with the pogo pins.

Closed Position

As the lever is fully engaged, the lid travels 0.34 vertically on linear bearings to bring the fixture into a closed test position. This vertical travel applies even compression force across the UUT as the pogo pins are engaged.

About Mechanical Press Fixture Kits

The mechanical press is a lever actuated vertical clamping press.When the lever is moved the top plate is lowered through a geared toggle clamp mechanism that multiplies the force being exerted by the operator so that large forces can be applied by the clamping mechanism without operator fatigue. The upper mechanism travels on precision rods and bearings that insure precise repeatability with each actuation and a long service life.

Fixtures can be removed from the press without tools by unscrewing the four thumb screws that hold down the top plate and the four thumb screws that hold the lower plate.

Press Clearance Dimensions

Don’t Miss: How To Do Marble Nails With Gel

Mechanical Press Fixture Kit #1012

The working area of the fixture plates that is unobstructed by the press mechanism is 10 in depth by 12 in length. In the raised position the working area between the moving clamp plates top surface is 5.75 and the lower side is 4.50. The top plate is shown mounted to the top of the moving mechanism where there is maximum clearance for the UUT but it can also be mounted to the underside if desired. When actuated the clearance between the upper and lower clamp mounting points is 1.635.

The following pictures show the press with personalized top and bottom fixture plates:

What You Can Receive From Xjtag Test Consultancy Services

XJTAGs offerings range from a full bespoke test design service to providing a single test or programming solution for integration into an existing ICT fixture. As an example, typical functionality included in a fixture might be:

- Full boundary scan test capability.

- Testing of power rails.

- Testing the boards external interfaces

- Clock frequency measurements.

Also Check: Supplements For Strong Hair And Nails

Mechanical Press Fixture Kit #9560

The working area of the fixture plates that is unobstructed by the press mechanism is 6 in depth by 9.5 in length. In the raised position the working area between the moving clamp plates top surface is 5.25 and the lower side is 4.50. The top plate is shown mounted to the top of the moving mechanism where there is maximum clearance for the UUT but it can also be mounted to the underside if desired. When actuated the clearance between the upper and lower clamp mounting points is 1.635.

Links To Store Categories

| For over 30 years Dave Gingerella has been a knowledge leader in the field of Electrical Test. Building thousands of custom fixtures for top companies around the world has brought him respect from others in the field. If you have questions Dave Gingerella is your answer. Feel free to contact Dave anytime with all your text fixture and product needs. |

Just some of our satisfied clients

| Test-X Fixture Products |

You May Like: Toenail Fungus Laser Treatment Indianapolis

In Circuit Test Fixture Systems And Fixture Kits

CheckSum pneumatic and mechanical test fixtures are rugged, reliable and inexpensive-especially when compared to the heavy vacuum fixtures required by traditional in circuit testers.

CheckSum fixturing is compatible with all of CheckSums test systems. Since the electronics are isolated from the fixture you can use CheckSums factory-built fixtures or build your own special fixturing or adapters that can accommodate ribbon-cable connectors.

CheckSum can provide fixture kits for your customization or do the complete fixturing and test programming job for you.

Bed Of Nails Interface Modules

Removable interface modules are the heart of the test fixture. They are responsible for fine alignment of UUT at device loading, provide electrical contact to the bottom side of the UUTs during test, and include custom wiring or an adapter board to route signals to your test interface of choice.

A floating tray on the interface module holds and aligns the UUT in a test-ready position above a bed-of-nails pogo pin array. Linear bearings with coiled springs on the interface module guide the floating plate and UUT onto the pins as the fixture reaches test position. Floating trays on the interface module can also be swapped out if there are changes made to the UUTs during the test process, eliminating the need to purchase entirely new modules for every iteration of a product design.

Read Also: Will Liquid Nails Stick To Concrete

Bed Of Nails Test Fixture Kits Jobs

Mobile test automation framework setup:Requirements:1. Setup a mobile test automation framework for both Android and iOS using the below tech stack.2. The framework should be based on cucumber, and scenario, scenario outline, data table examples should be used.3. The framework should be a page object model driven.4. The test data should be handled separately.5. The framework methodsTech stack:1. WebdriverIO2. Appium3. Cucumber4. Typescript5. MocksUse any demo app which has a login and have options to scroll and swipe.

1: OTP to change to email when admin wants to clean database data in the panel, OTP code is sent to mobile.Can we change this OTP to system admin email address? 2: pls add favicon icon.3: Deploy the system on the cpanel and just test if okay.

An anti-hacking expert wants to test your website.Start as ‘Anti-Hacking Expert’

Small additional amendmentsSource code includedTesting of admin panelProgrammer will need a server to test

Checksum Pneumatic And Mechanical Test Fixtures Are Rugged Reliable And Inexpensive

CheckSum fixturing is compatible with all of CheckSums test systems. Since the electronics are isolated from the fixture you can use CheckSums factory-built fixtures or build your own special fixturing or adapters that can accommodate ribbon-cable connectors.

CheckSum can provide fixture kits for your customization or do the complete fixturing and test programming job for you.

12KN Dual Level Long-Travel Pneumatic Fixture System

The 12KN Dual Level Pneumatic Fixture System is integrated into a rack-cabinet and designed to be the basis for CheckSum bed-of-nails test systems. The long-travel press eliminates the need to open and close a lid between tests. The fixture kits are easily changed by sliding the fixture top plate and base into place. The system uses a universal spring-probe fixture interface. The fixture system can accommodate up to 5200 test points and uses standard CheckSum fixture kits. Integrated into the system is rack space for system electronics and an operator keypad with a minimum selection of buttons to make it easy, safe, and error-free for the operator to use. The 12KN is compatible with existing CheckSum KIT1000-QC and KIT2KN-QC fixtures. A safety light curtain provides operator safety.

Fixture Guidelines: Assembly size can be up to 24 x 13.2 inches , dual level, single-sided and double-sided probing plus TestJet.

TR-7-1000-QC Pneumatic Fixture System

TR-5-400-QC Mechanical-Advantage Fixture System

TR-5 Mechanical Bed-of-Nails Fixture Kits

Also Check: How To Take Dip Powder Nails Off