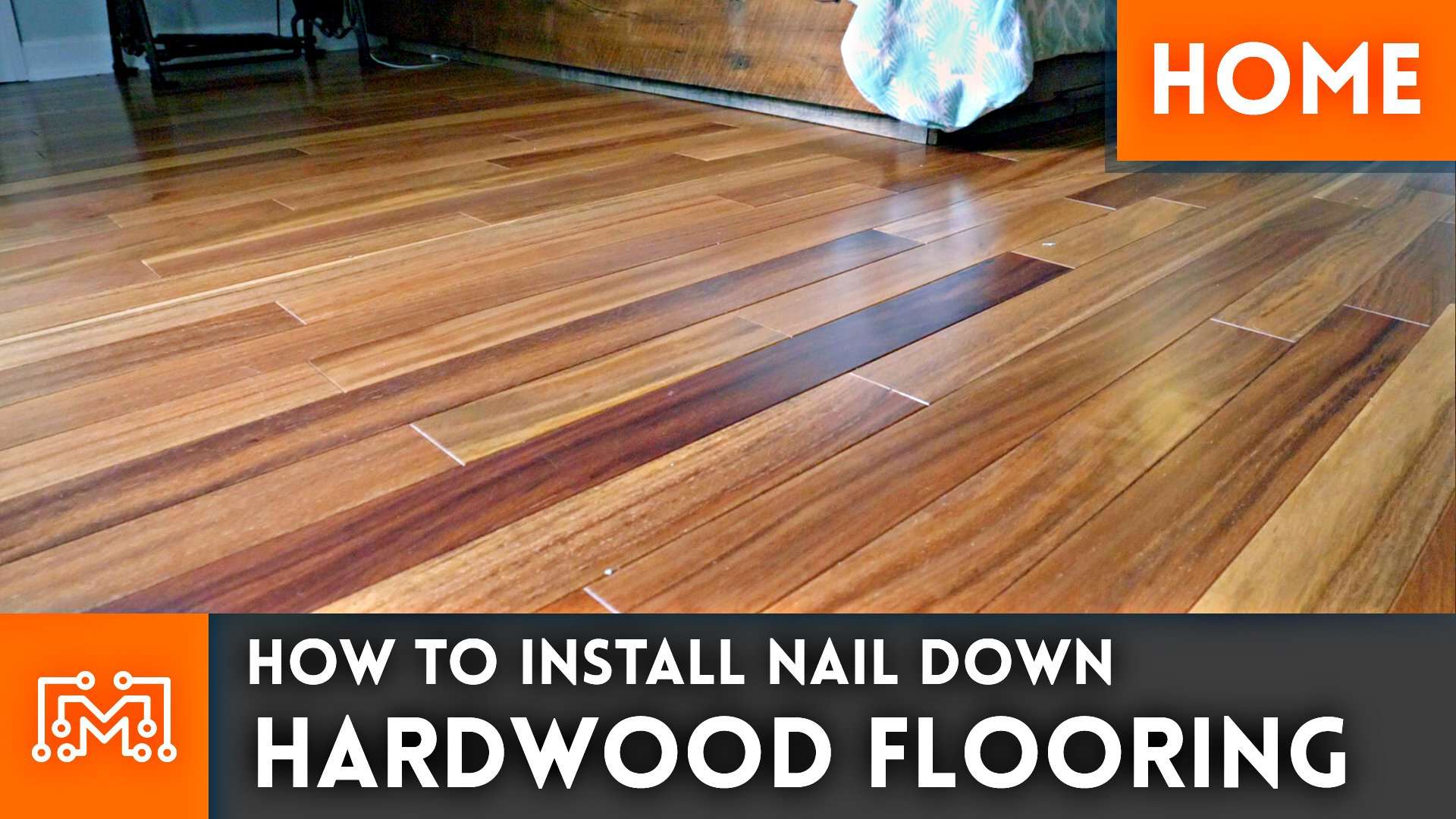

Glueing Vs Float Vs Nail Down Flooring Installation Which Is The Best Method

The longevity of your hardwood flooring depends on how it has been installed. Glueing, nailing and floating are some of the popular methods of flooring installation. The species of hardwood, the design of the floorboards, thickness, subfloor, appearance and durability are certain factors which should together influence your decision. Each method poses certain advantages and disadvantages and there is no absolute answer as to which the best is.

This post outlines the various features, pros, and cons of the different installation methods and compares them to help you while taking a decision regarding the best method for your home.

- Nail-down

This is the commonest method of installing a hardwood floor. If you have wooden or plywood subfloor, the floorboards are directly nailed on it by this method. The method of nailing is called blindly nailed where the nail is angled at 45 degrees and nailed through the tongue. The tongue is the protruding portion of the wood planks that fit into the groove of the adjacent board. Hence, it is nearly invisible once the installation is complete.

Some advantages of this method:

- It is the cheapest and the fastest method of installation

- It is suitable for both hardwood and engineered hardwood floorboards

- The floorboards will be firmly set against the sub-floor

On the other hand, some major drawbacks of this method are:

- Glue-down

On the downside,

- Floating

However, this method has some disadvantages as well that you must be aware of:

- Cost

Hardwood Flooring Installation Methods: Fasten Vs Glue

Many people spend a great deal of time selecting the right hardwood flooring product. However, it is also important to carefully consider the installation process. There are three common installation methods from which to choose: fasten, glue-down, and floating. Here we will look at the benefits and drawbacks of each method, which will help you choose the best strategy for your circumstances.

How To Install Hardwood Floors On Concrete

Do you know how to install hardwood flooring on concrete slab regardless whether your floor is on the second floor, at ground level or in the basement? Youll find concrete floors in almost every home. This article will focus on basement installations. However, the information applies to installing hardwood floors over concrete at any level.

Most of the articles youll find online will recommend installing a floating floor made of engineered wood. But what if youre set on having a solid hardwood floor in the basement? Most hardwood flooring companies wont honor the warranty if you install their flooring in the basement.

There is one company that allows for basement installation, and it wont affect the warranty as long as youve installed it per their instructions. Well tell you who it is in a moment.

Have you ever wondered why solid hardwood floors is a better choice for your basement wood flooring options?

Recommended Reading: Nail Tech Schools Cost

Prepare The Area For Hardwood Installation

Start by pulling the baseboards and check the subfloor to make sure its level and smooth. If you dont have a subfloor, youll need to add one. Indicate where floor joists are and cover the floor with underlayment.

A 15- to 30-pound asphalt-saturated felt or silicone shield or vapor barrier paper works well to inhibit moisture and protect floors and subfloors from spills and water vapor from the ground underneath.

Build A Plywood Subfloor

Most subfloors over concrete use exterior grade ¾ plywood or OSB . It lays directly on top of the waterproof barrier, or combination of barrier and underlayment, to help cushion and insulate. Be aware of the additional height that the subfloor and underlayment add. They can add up to two inches in a basement that may already have a low ceiling.

There are many options for building a plywood or OSB subfloor. This video demonstrates a cost-effective method for DIYers.

A subfloor allows you to nail or screw into the wood instead of concrete. While this saves time from not having to drill pilot holes first, it still adds to the cost of installing a floor. A better solution is laying a floating floor.

Also Check: Can You Use Glue On Impress Nails

Set Another Chalk Line

Depending on what width hardwood you are installing this line will be different. Our job calls for a 3 1/4″ wide prefinished Bruce Winter White product. Incidentally, this was a cabin grade product installed in 2003, purchased off the internet, with the customer full aware of what to expect with a cabin grade hardwood.

Considering solid wood floors are started with tongue facing out, I used our 3 1/4 inch board width and added 1/4″ for the tongue. This insures the chalk line is not covered and can be seen easily. By adding another 3/8″ inch for expansion our line was measured 3 7/8″ off the drywall.

Tools And Accessories Needed For Nail Down Hardwood Floor Installation:

- Power Miter saw

In summer, when humidity is high, hardwood flooring absorbs the humidity in the air and expands. The expansion causes the strips/planks of wood to push against each other. This is referred to as cupping. These variations can be minimized with proper ventilation and dehumidifying. On the other hand, in winter, the relative humidity level at home is much lower due to the usage of heating system. The lower humidity level results the wood releases its humidity and the strips/planks contract or shrink. It is then recommended to use a humidifier to minimize extreme shrinkage effects.

Before you nail down hardwood, flooring must be stored in a controlled environment within the above mentioned temperature and humidity. In order to meet minimum installation requirements for moisture content, materials should be delivered 72 hours prior to installation or as long as necessary for the hardwood flooring to acclimate. Acclimation within a closed carton may not be adequate due to lack of air movement. Handle and unload with care, then store the flooring in a dry place and provide air space under cartons. Do not unload or transport flooring during wet conditions because the wood will absorb moisture, which will cause it to swell. The swelling of the wood will cause installation problems, because eventually the wood will shrink back to its normal moisture content, and the resultant shrinkage may produce gaps in the finished flooring.

Also Check: How Do I Get Nail Polish Out Of Clothes

Request A Free Easiklip Sample

Feel the quality for yourself by ordering a free Easiklip sample pack. You will receive a 5″ sample of each of our floor types to see which one fits your decor:

- Natural Oak

- Rustic Smoke Stain

- Rustic White Bleach

Youll also get two aluminum clips to test and see how it snaps into place. These samples come from the same White Oak boards that we use in all our floors.

There is no better way to improve your home than by choosing Easiklip for your basement hardwood floor.

With Easiklip, No Nails, No Glue, No Fuss.

Choose The Proper Floor Stapler

- For products up to 3 wide and 1/2 thick, use use a 20 gauge, 1 staple with a 1/8 crown.

- When installing a 5 wide product, use an 18 gauge 1-1/4 staple or longer with a 1/4 crown.

- 3/4 thick, engineered planks should be nailed or stapled using a 3/4 solid wood flooring nailer or stapler of any brand. You must use the recommended size staple or cleat for 3/4 solid wood installations you must also use the recommended nailing schedule, which is 1 to 3 from the ends, and 8 to 10 in the field.

- Note: you must use an appropriate adapter for the thickness of the wood on some flooring staplers.

Also Check: How Much Does Nail School Cost

Install A Moisture Barrier For Best Results

Concrete is very porous like a sponge. Water can quickly pass through it causing moisture problems, especially below grade. Before installing any wood floor over concrete, youll need a moisture barrier. Typically, it is sheets of plastic laid on the slab and taped at the seams with waterproof tape. It will extend up the wall for about 2 to 3 inches, creating a bowl where your wood floor stays dry and protected. Watch this video to see how easy it is:

There are other moisture barrier options. Ask your flooring professional what he or she uses.

Once you know the slab is level and dry, and you have a moisture barrier in place, its time to look at basement subfloor options and how youll install your new hardwood floor.

What Type Of Nail Gun For Hardwood Flooring

A flooring nailer is the preferred type of nail gun for installing hardwood flooring. This is because the flooring gun is specifically designed for punching nails at the correct angle into the thin sheets of hardwood flooring commonly used in homes and offices around the world.

BOSTITCH 2-in-1 Flooring Nailer See Price & Details

When doing hardwood flooring, you have to nail at an angle -usually 45-degree downwards- into the joist or subfloor to ensure that the wooden panels are secured with no gap between them. This is called blind nailing which is different from face nailing.The design of the flooring nailer makes blind nailing an easy task.

If you do not have a flooring nailer, then a finishing nailer or a Brad nailer is probably the next best hammering power tool to use. However, you will need to use it in the right way to get the same results as a flooring nailer. This means that you will need to choose the correct type of nail and shoot it in at the right angle if you want the Brad nailer to work properly in securing hardwood flooring.

With a brad or finish nailer, you may also want to increase the depth setting to ensure that the head is not protruding out. If you are using the old fashion hammer and nail, you should use a nailset to countersink the nail head into the material.

Don’t Miss: What Is Green Nail Syndrome

Nailing Down A Quality Hardwood Floor With Osb

Hardwood floors are popular for their striking grain patterns, rich colours, and natural beauty. Their eye-catching esthetic is not solely dependent on these surface characteristics, however, as what goes under a floor is often as important as the finish material itself.

As the support structure for the flooring, a sound subfloor provides stability underfoot and helps enable a high-quality finish. Excess moisture in the substrate can damage overlying hardwood flooring, potentially creating cupping, cracking, or other defects.

To ensure a first-rate, visually appealing hardwood floor, building professionals are increasingly using oriented strandboard subfloors. Engineered to optimize value and performance, OSB panels are typically more consistent than plywood, knot- and void-free, and lower in cost. OSB panels provide a flat, solid base for floorcoverings, and help yield even, stable, and long-lasting floor finishes.

OSB attributesOSB is a structural panel with uniform strength and stiffness. Manufacturers produce the material by applying durable adhesives to thin wood strands and aligning them into layers of alternating strand orientation for strength. The stacked layers form large mats, which manufacturers bond together under high heat and pressure.

InstallationContractors can saw, drill, sand, and fasten OSB panels easily with standard tools, though carbide-tipped blades tend to wear best.

Regular Nails Vs Cleat

The regular nails with different head designs and smooth body are meant for securing the pieces in position by preventing them from sliding. They do not have sufficient holding power to keep the pieces tight.

On the other hand, the staple and cleat are designed for holding the wood tightly and securely in position.

Don’t Miss: How To Get Nail Polish Remover Out Of Clothes

What Types Of Nails Are Used

In the golden days, steel hardened cut nails were used. Now depending on what tool you may be using there are cleat nails, manufactured with a barbed like appearance on the bottom that helps hold the flooring into the subfloor.

Staples on the other hand, gain their strength by not only a two pronged approach but also through the use of a hardened glue resin coating. Once the staple is engaged by a pneumatic tool, friction caused by the force going through wood and subfloor heats up the resin acting as an adhesive.

The Process Of Blind Nailing

Before flooring installers had power nailers, they had to blind-nail all flooring boards by hand. The process involves driving a series of nails into the tongue of a floorboard at 45-degree angles the angle allows each nail to push the board against the one next to it as well as hold the board to the floor. Each nail is fully set when the head is flush with the tongue, and because it’s angled, it doesn’t interfere with the groove of the following board as it fits around the tongue and hides all the nails on that tongue.

Also Check: How Much Money Does A Nail Tech Make

Engineered Flooring Requires Acclimation

Just like solid hardwood flooring, engineered flooring needs to be acclimated to its environment before installation. Consult the specific manufacturer for their acclimation process.

Do not store engineered wood flooring in basements or garages where humidity levels are higher.

To allow for proper acclimation, the heating/air-condition system must be operational for least 14 days prior to installation and thereafter at a temperature of 65°F 75°F to reach desired humidity level. The relative humidity level at home should be controlled between 35% 55% at all times prior, during and subsequent to installation.

To ensure the flooring is properly acclimated and has achieved equilibrium moisture content with the surrounding ambient conditions, you need to measure the MC in the wood planks. Whether installing on a concrete or wood substrate, always reference the NWFA Installation Guidelines for the appropriate method of installation.

According to the National Wood Flooring Association guidelines, moisture readings of the subfloor should be no more than 13% on average . And, depending on the flooring manufacturers installation guidelines, there should be no more than 2% MC to 4% MC difference between properly acclimated wood flooring and the subfloor.

Tip: Test the subfloor moisture in several locations taking note of higher readings. Higher readings indicate a moisture problem that needs to be addressed before installation can begin.

What To Complete Before Flooring Installation

The building must be completely closed in with all outside doors and windows in place. All wet work should be thoroughly dry. The wall coverings and painting should be completed before you nail down hardwood flooring.

In order to avoid damage caused by moisture, make sure basements and under-floor crawl space are dry and well ventilated. Plastering and concrete work must be completely dry with minimum of 90 days curing time. Freshly poured concrete slabs emit many gallons of moisture as water vapor, therefore no concrete should be poured after the flooring is installed.

Exterior grading should be complete with surface drainage offering a minimum drop of 3 in 10 to direct flow of water away from the structure. All gutters and downspouts should be in place.

Solid hardwood flooring only can be installed on or above ground level with a plywood subfloor. Engineered flooring can be installed above grade, at grade and below grade level. Do not install hardwood flooring in bathrooms. Always check with the manufacturers instructions to determine if your hardwood floor can be installed over an in-floor radiant heat system.

Don’t Miss: How To Get Rid Of Fingernail Fungus From Acrylic Nails

Should You Nail Or Glue Down Your Hardwood Floors

Theres a great feeling in having your hardwood floorsdelivered to your home and knowing the last step is soon approaching. Allthats left to do is install your beautiful hardwood floors! There are twoadhering options to consider before proceeding to the installation phase. Youcan either nail down your hardwood floors or glue down your hardwood floors.Seems like a simple choice, right? It can be as long as you take time tounderstand a few things. Homes with a concrete subfloor should have their hardwoodsglued down while a wooden subfloor allows for either option. The subfloor prepis especially critical for the glue down option. The glue down method meansthat the flooring is glued directly to your subfloor. The nail down methodmeans that the flooring planks are nailed to your wood subfloor. While both ofthese methods get the job done, you need to read up on the details behind eachoption before you proceed. Lets discuss the pros and cons before you install.

NAILING DOWN YOUR HARDWOODFLOORS

GLUING DOWN YOURHARDWOOD FLOORS

Article contributed by Kimberly Fairfax McPheron, Local Columbus Blogger

Engineered Floors Can Have Problems

Some engineered floors have reportedly emitted toxic fumes. It can be caused by the amount of adhesive used in the construction of the materials and gluing the veneer to the top.

Another issue is improper installation. If an installer nails the engineered floor too close to the edge, it can crack the board causing dangerous splinters lurking underfoot that can be up to 3 inches long in some cases.

You dont have those concerns with a solid hardwood floor.

Don’t Miss: Braggs Apple Cider Vinegar Toenail Fungus

Safe & Healthy Floors: Perfect For Any Home

Ambient is FloorScore® Certified, which means you dont have to worry about dangerous off-gassing of toxic chemicals. FloorScore® is recognized by more than 19 leading environmental programs. The FloorScore® seal is your guarantee that a product has been independently tested and scored by SCS Global Services.

Plus, all of our adhesives and finishes are either ultra-low or zero-VOC. Your indoor air quality isnt something youll have to compromise when installing an Ambient bamboo floor!

All Ambient floors are Lacey Act Compliant, which is your assurance that theyre legally sourced with minimal damage to the environment.

Add in one-stop shopping ease, great prices, honest reviews, and youve found the best place to buy your bamboo flooring. Shop our bamboo and eucalyptus floors today!