What Type Of Nails For Felt/underlayment

Roofing felt is a type of underlayment that professionals install beneath a roofs shingles. Unlike selfadhering underlayments, such as ice and water protector, felt underlayment needs to be fastened in place with nails. Specifically, youll need roofing cap nails. These have large plastic caps for heads, which help prevent water intrusion.

Dont confuse these cap nails with gasket roofing nails. Roofing nails with gaskets are intended for metal roofs. The gasket is rubber, not plastic. You want roofing nails with plastic washers for roof underlayment.

How Many Nails Per Square

Estimating your roofing materials is key to your success, so youll want to know how many nails youll use in a square. That depends on the exposure and coverage of your shingles. With higher coverage, youll lay down fewer shingles in a square and therefore use fewer nails. For example, when using Cambridge shingles, youll use roughly 240 nails, because of their Advantage size. If youre installing by the High Wind Application, youll use two more nails a shingle, so 360 nails per square.

Is Cdx Or Osb Better

CDX and OSB are used for almost similar things, but because they have different features, one is better applied in some tasks and the other one on other tasks. CDX is best for sub-flooring. OSB also seems to be good for roof sheathing. But take care, it also requires that you use water-resistant coating at the edges.

Recommended Reading: How Do You Get Dip Nails Off

Calculating Proper Roofing Nail Length

The length of the roofing nail is determined by the material it will be drilled into. Some materials require longer nails, while others do not need a lot of penetration and work with shorter ones.

- Some materials like sheds or garden houses have roofs which work just fine with less penetration of the nails.

- For materials like solid wood, plywood, OSB, and non-veneer wood decking, the nail should go in 19mm.

- If you are installing thick shingles or doubling the roof by adding shingles over shingles, then the nails need to be at least 30mm to 35mm long.

Nails that are properly seated will penetrate the roof deck about three-fourths of an inch. If the roof deck itself is three-fourths of an inch thick, then the nail should penetrate at least one-eighth of an inch through the roof deck.

What Size Osb Should Be Used For Roofing

Typical types of wood used for roof sheathing are oriented strand board, known as OSB, and plywood, the most popular being OSB. Sheets of 7/16-inch thick, with no edge support, can be used in an area where the snow load is 30 pounds per square foot. With edge support and the same snow load, 3/8-inch OSB can be used.

Read Also: How To Take Off Powder Nails

What Is The Best Osb For Roofing

With 24-inch truss/joist spacing, the National Wood Flooring Association recommends 1-inch OSB underlayment, compared to 7/8-inch plywood. Depending on thickness, plywood is also approximately two pounds or more lighter per sheet. Perhaps, plywoods biggest feature is the homeowners perception of higher quality.

Problems With Roofing Nails And Installation

A number of problems can occur with wrongly sized nails installed in roofs. The structure of the roof, alongside its attachment to the house, can be affected.

- Nails not drilled properly can cause materials such as wood and timber to splinter over time. The gaps and cracks created by those splinters can be problematic because they would allow things to pass through. Another problem would be moisture that can form in the gaps and deform the shape of the wood or cause molds to grow in these spaces.

- Using longer nails than required when driven into roofs may cause cracks and those nails to loosen and come out.

- If nails are overdriven, then there is likely to be breakage in the shingle. They may also go all the way through and form holes in the shingle, making it unworthy of use.

- If nails are under driven, they can create air bubbles making the roof vulnerable to wind damage.

Installing roofing nails seems like a small task however, if not done correctly, it can lead to costly expenses in the long run to fix and redo. Gaps, holes, or cracks made because of improper installation can cause expansion or contraction in the roofing material, which can damage the entire deck.

Don’t Miss: Nailer Reviews

Not Putting The Nails In The Right Spot

Another nailing mistake when roofing is placing the nails in the wrong spots. Having the nails too high up on the shingle is a problem. They should be one inch from the cutout and one inch from each edge. If the nail catches the top edge of the shingle below it, that is the correct location. That protects them from wind and blow off.

What Type Of Nails For Sheathing

If you need to install new roof decking or OSB, youll need to nail it to the roof truss. There are fewer requirements for these nails than those used to secure shingles. Common nails, or even wood screws, may be acceptable nails for OSB roof sheathing. You should check with your building code and local bylaws to confirm.

Recommended Reading: How To Remove Impress Nails

Can I Use 7/16 Osb For Roof Sheathing

Roof sheathing is the structural support for your roofs exterior. OSB is the most common choice for roof sheathing because of its flexibility and low price point. However, despite the popularity, some buildings require stronger support like plywood which can withstand heavier loads. This is because plywood tends to require thicker roof decking compared to OSB.

The most common roof sheathing thickness is 7/16. 7/16 is durable and maintains building integrity much longer than other sizes. Many people recommend going no lower than 5/8 thickness to maintain durability, especially when using OSB. You may notice that 3/8 is a common choice for roof sheathing, however, it is not as durable as 7/16 and does not typically abide by modern code requirements.

The APA stamping on roof decking is beneficial to determining appropriate thickness when deciding upon different roof sheathing thicknesses. Always remember the board you choose must support your roof and the weight you intend to bear on top of it. The roof decking must also be resistant to aging and heavy loads, including harsh weather .

Types Of Roof Sheathing

There are many types of roof decking that you can use for roof sheathing. Depending on your structural requirements and budget, different roof boards may be preferable to others. You should also take into consideration the location and intent of your build.

For instance, if you are building an outdoor gazebo, you might want to invest in more weather-resistant roof sheathing that can withstand the elements.

Here are a few key types of roof decks used for roof sheathing:

Don’t Miss: How To Easily Remove Dip Nails

Roof Sheathing Code Requirements

Roof sheathing code requirements vary per state, but the guidelines are the same regarding the quality and ventilation of roofs. Generally, roof sheathing cannot be less than 3/8, and even then, some jurisdictions require thicker wood. Similarly, different projects will require different thicknesses.

To better understand which thickness your project requires, you can reference the APA wood guidelines provided on the roof paneling. Using this stamp and your trusses, you can calculate the right roof sheathing thickness for your new build!

How Roof Shingles Are Installed

The specifics of how shingles are laid on your roof vary by manufacturer.

Some roofing shingles, such as Duration®, are applied with a 6-1/2-inch offset and a 5-5/8-inch exposure over a prepared roof deck. Contractors start at the bottom of the roof and work across the roofs surface and up.

Proper overlapping covers up the nails and provides a seamless, attractive look to your roof.

Recommended Reading: How To Take Off Dip Nail Polish

What Size Nails Do I Use For Plywood

Nails for Subfloor Nails approximately 2 inches in length pass through the ¾-inch plywood and still provide plenty of length to secure the plywood to the joists. Realtor.com recommends an 8d nail , which is roughly 2½ inches, to pass through the plywood and bury nearly 2 inches of the nail in the joists below.

Which Is Better 5/8 Or 7/16 For Roof Sheathing

5/8-inch paneling is a better choice for roof sheathing than 7/16-inch paneling. This is because of the durability and structural integrity that this additional thickness will bring.

Although 7/16-inch paneling is considered the most common choice for roof sheathing, 5/8-inch roof sheathing is typically one of the best sizes to use when selecting roof sheathing. However, 7/16 paneling is a bare minimum requirement and therefore increased thickness is suggested for heavier builds.

Read Also: Tips For Applying Color Street Nails

Proper Nail Application For Asphalt Shingles

Reading Time: 3 minutes

Required by the International Building Code, proper nailing is essential to the optimum performance of roofing shingles. Accurate nailing requires the use of approved nails, nail-driving methods and placement .

Atlas has installation guidelines in place to ensure proper, uniform installation of Atlas shingles on every roof, whether that roof is new or recovered. Nails should have a minimum, nominal shank diameter of 11- or 12-gauge, and a minimum head diameter of three-eighths of an inch. The length of each nail must be a minimum of 1¼ inches long, and for roof-overs, Atlas recommends a nail length of at least 2 inches.

Nails of the proper length should penetrate three-fourths of an inch into the roof deck. However, where the roof deck is less than three-fourths of an inch thick, the nail should be long enough to penetrate fully and extend at least one-eighth of an inch through the roof deck.

Each shingle model has specific requirements for nails printed on each shingle wrapper. These guidelines must be followed to comply with building codes and ensure intended performance levels

All nails need to be driven either by hand or with a properly adjusted pneumatic nailer. Improper adjustment of a pneumatic nailer can result in overdriven or underdriven nails, which can cause nail corrosion, sealing failures, raised tabs, buckling and blow offs.

For more information about proper nail placement, visit atlasroofing.com/roof-shingles.

The Importance Of Nails In Roofing

Every time there is a gust of wind, we rely on the nails weve chosen to hold new shingles in place. Choosing the right roofing nails and driving them properly is essential for getting the best performance out of your roof. For more tips on roof installation and tools, read our article about choosing between a nail gun and a roofing hammer.

Don’t Miss: How To Get Nail Polish Out Of Shirt

Staples V 8d Common Nails For Sheathing

Staples v 8d Common Nails for Sheathing?

If medium crown power driven staples are use instead of 8d common nails for fastners on roof or wall sheathing , is the nailing schedule the same as code requires for nails.

What length of staple should be used .

And, what is the proper orientation of the staple crown .

Are there any structural integrity advantages of one fastener over the other?

Thanks

Where do you live? It is my understanding that in some states staples are not allowed to be used for roof sheathing. I’m not sure about wall sheathing. Your building inspector can tell you, or it will say something in the buiding code.

I have never seen a code concerning staples even though we have used them for about 25 years on sheathing and decking. We use the 2 inch long by 12 inch crown staple and we put them 90 degrees to the rafter or stud. On the joints we put the staples parallel to the rafters or studs. The holding power is tremendous. We put the staples about 10 inches apart. WE have used the framing gun and shot #8 sinkers. The duo fast guns I use come with an extra tip to put on the nose so that the #8 nail does not shoot through the decking. The staple gun is much faster.

James Hart

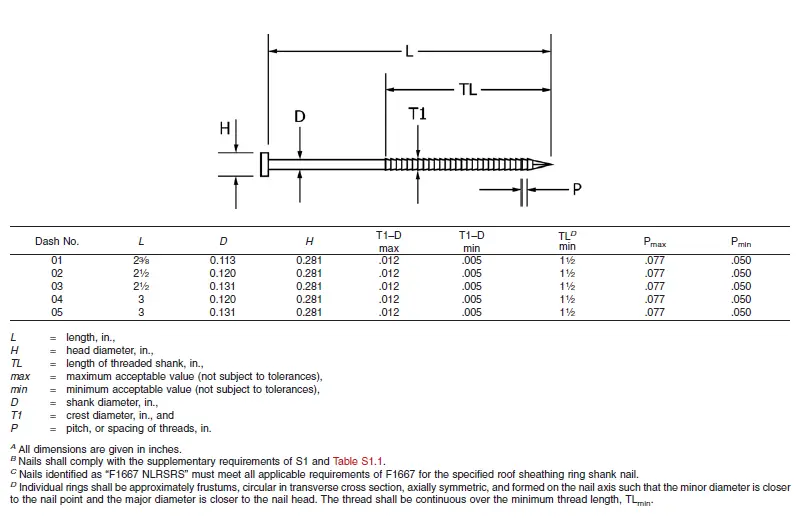

No staples in Florida. And, to top that, the new codes will be requiring ring shank 8’s for roof sheathing . No more 8d commons and most likely no more alternates like the 8d CC’s for high wind areas.

kinda on this subject, a short article from JLC nov-04

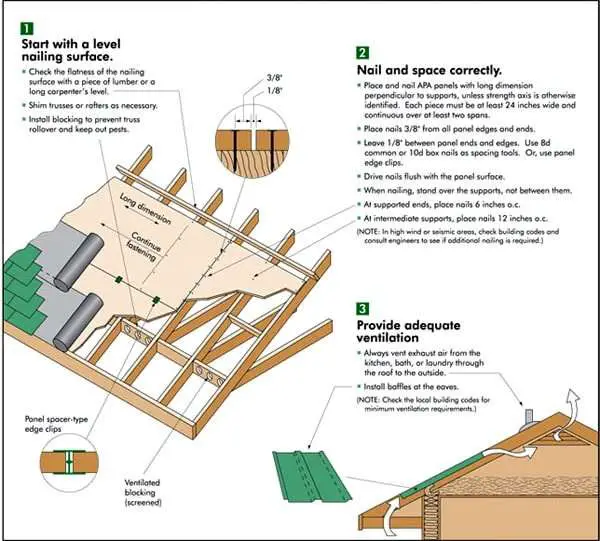

Fasten Roof Sheathing Panels Properly

Fasten panels with a minimum of 8d Common nails spaced a maximum of 6 inches on center at supported panel ends and edges. At intermediate supports, fasten panels 12 inches on center. In high-wind areas, more fasteners may be required. Fasteners should be 3/8 inch from panel ends and 3/8 inch from panel edges .

For pitched roofs, wear skid-resistant shoes.

On panels with a screened surface or skid-resistant coating, install panels with the non-skid surface up.

Don’t Miss: Green Spot Under Acrylic Nail

Which Is Better 7/16 Or 1/2 Osb For Roof Sheathing

7/16-inch OSB is the most common choice for modern roof sheathing, but that does not mean you should use it in every build. This is only slightly smaller than ½-inch roof sheathing, but some people say there is a noticeable difference in using it for roof sheathing because of its weight-bearing potential.

If you plan to build something that requires extensive weight-bearing, choosing ½-inch paneling is a better option because of the additional support.

Cover Roof Sheathing With Shingle Underlayment Felt

Unless otherwise recommended by the sheathing manufacturer, cover the sheathing with shingle underlayment felt to minimize exposure to weather.

Use shingle underlayment felt conforming to ASTM D226 Type I, ASTM D4869 Type I, or ASTM D6757 or check roofing manufacturer’s recommendations if delays are anticipated during construction. Remove wrinkles and flatten the surface of the shingle underlayment before installing asphalt or fiberglass shingles.

Read Also: Nonyx Nail Gel Para Que Sirve

Is Osb Or Plywood Better For Roof Sheathing

Plywood Holds the Moisture Advantage Over OSB

When plywood gets wet, it tends to swell. OSB takes longer than plywood to get saturated, but also takes much longer to dry out. When used as roof sheathing, this tendency to hold moisture means it will degrade faster than plywood when exposed to chronic leaks.

Become A Gba Prime Member And Get Instant Access To The Latest Developments In Green Building Research And Reports From The Field

Im sure your roofing manufacturer would have available downloads of their installation manuals. As I read a CertainTeed shingle installation manual , does not mention a word on cutting off any nails. “Nail shanks must be long enough to penetrate the roofing and then go ¾ into solid wood, plywood or non-veneer wood decking, or through the thickness of the decking, whichever is less.

David, I disagree with your interpretation. Every time I read a requirement that says that 3/4 inch is “the minimum penetration of a roofing nail into roof sheathing,” I interpret that to mean that the nail needs roof sheathing that is at least 3/4 inch thick, and that the nail must stick out the back side of the sheathing at least a tiny little bit.

So, I think you need 3/4 inch plywood or solid board roof sheathing.

Some time ago roofing nails did not penetrate the deck. Thicker decks and shorter nails. I remember the difficulty twirling those 1″ roofing nails. This had two benefits: 1) a neater looking attic, and 2) no condensing or frosting points. The downside, I think, is that the shrink-swell process in wood that “walks” the nail out of the deck can happen more easily.

I’ve had historic jobs where I requested clipping the protruding nails with a bolt cutter.

David, I’m confused. If the roof is done, you should be able to answer the question of whether the building has 1/2-inch roof sheathing or 3/4-inch roof sheathing.

Don’t Miss: Does Hongo Killer Nail Formula Work

Staples Or Nails Choosing The Right Fastener For Wall And Roof Sheathing

Home » Articles » Staples or Nails? Choosing the Right Fastener for Wall and Roof Sheathing

We are often asked by contractors if they can substitute framing staples instead of nails for their wall and roof sheathing fasteners. There is no easy universal answer to this question because the location of the project may place it in a high wind or seismic zone that may require special engineering for the fastening systems. However, according to the International Building Code, there is a fastening schedule under Table 2304.9.1 that lists the approved equivalent fasteners for nails and staples in a wide array of assemblies not subject to these special engineering conditions.

For example, according to the table, 7/16 OSB wall sheathing may be fastened with 6d common, box or casing nails OR 1-3/4 16 gage staples at 6 on center at the panel edges and 12 on center in the field . Similarly, 19/32 OSB roof sheathing would be 8d common, box or casing nails at 6 on center at the panel edges and 12 on center in the field OR 2 16 gage staples at 4 on center at the panel edges and 8 on center in the field.

What Size Roofing Nails Do I Need

What size roofing nails to use?

Composition ShinglesComp Shingles Sheathing Thickness 3/8 1/2 5/8 3/43-Tab comp shingles 1 1 1 1Dimensional comp shingles 1 1-1/4 1-1/4 1-1/43-Tab comp shingles over 3 Tab comp shingles 1-1/4 1-1/4 1-1/4 1-1/2Dimensional comp shingles over 3 Tab 1-1/4 1-1/2 1-1/2 1-1/2

*More than 1 layer of roofing not recommended over 3/8 Sheathing

Wood ShakesWood Shakes Nail Type Minimum Length18 Straight Split 5d Box 1-3/418 and 24 Handsplit and Resawn 6d Box 224 Tapersplit 5d Box 1-3/418 and 24 Tapersawn 6d Box 2

Wood Shingles Wood Shingles Nail Type Minimum Length18 Straight Split 3d Box 1-1/418 and 24 Handsplit and Resawn 4d Box 1-1/2

DisclaimerThe above nail sizes are recommendations only. Consult your local building department for specific nailing applications.

Also Check: How To Remove Contact Lenses With Nails