Test Pins / Probes For In

There is a great variety of different types of pin or test probe that can be used for in-circuit test fixtures.

The in -circuit test probes or test pins or probes are spring loaded and comprise a barrel with its internal spring, and the plunger. The test probes fit into a socket that enables them to be replaced when they become worn of damaged.

The major design changes are within the head or tip that contacts the board under test. Each type of head has a particular application for which it is best suited.

- Concave tips: These in-circuit test probes are often used for connecting on to terminal posts.

- Spherical radius convex tips: These may be used when mating with an edge connection on a printed circuit board.

- Cone tips: This format for an in circuit test probe is often used for mating with a PCB via hole, or directly onto a PCB track..

- Single pointed tips: These are often used for mating with solder joints as the tip is able to penetrate the oxide film on the solder to make good contact.

- Multi-pointed tips : These may be used when a connection is required through a larger area of solder – the multiple serrations mean that several points of contact can be made through the oxide layer on the solder. They may also be used to mate with the connection to a conventional component, i.e. not surface mount. The probe serrations will connect to the solder and wire that protrudes through the board.

More Test Topics:

Common Test Press Bases

Test press bases use robust stainless steel and ball-bearing linear guides for smooth vertical compression. This ensures consistent, repeatable, and reliable test results while preventing damage to the UUT or test probes during use.

Smaller 750 series test presses utilize a combination of clamshell and vertical guide designs while larger 752 series test presses are fully vertical.

Open Position

The lid sits at a 50 angle when the press is in the open state, giving the operator ample room to load and unload UUT between test. The height of the interface module and length of standoffs on the lid impact this working area.

Resting Position

As the lever is pulled to close the lid, it first comes to rest in a horizontal position parallel to the baseplate. The standoffs installed on the lid sit above the UUT without making contact and the UUT does not engage with the pogo pins.

Closed Position

As the lever is fully engaged, the lid travels 0.34 vertically on linear bearings to bring the fixture into a closed test position. This vertical travel applies even compression force across the UUT as the pogo pins are engaged.

Free Pcb Inspection Will Be Carried Out On All Pcbs Manufactured By Pcbcart

As a China PCB Manufacturer, PCBCart has been spending full energy in striving for the high quality of printed circuit boards while keeping the PCB production cost-effective. 100% electrical test has to be performed on each piece of PCB boards prior to their playing a real role in customers’ projects just to guarantee the smooth implementation of optimal performance and functions, which has been a crucial link in our PCB fabrication process. If your required test items aren’t covered, please send us a message. We’ll work out a solution at very short time.

Read Also: How To Treat Nail Fungus Fast

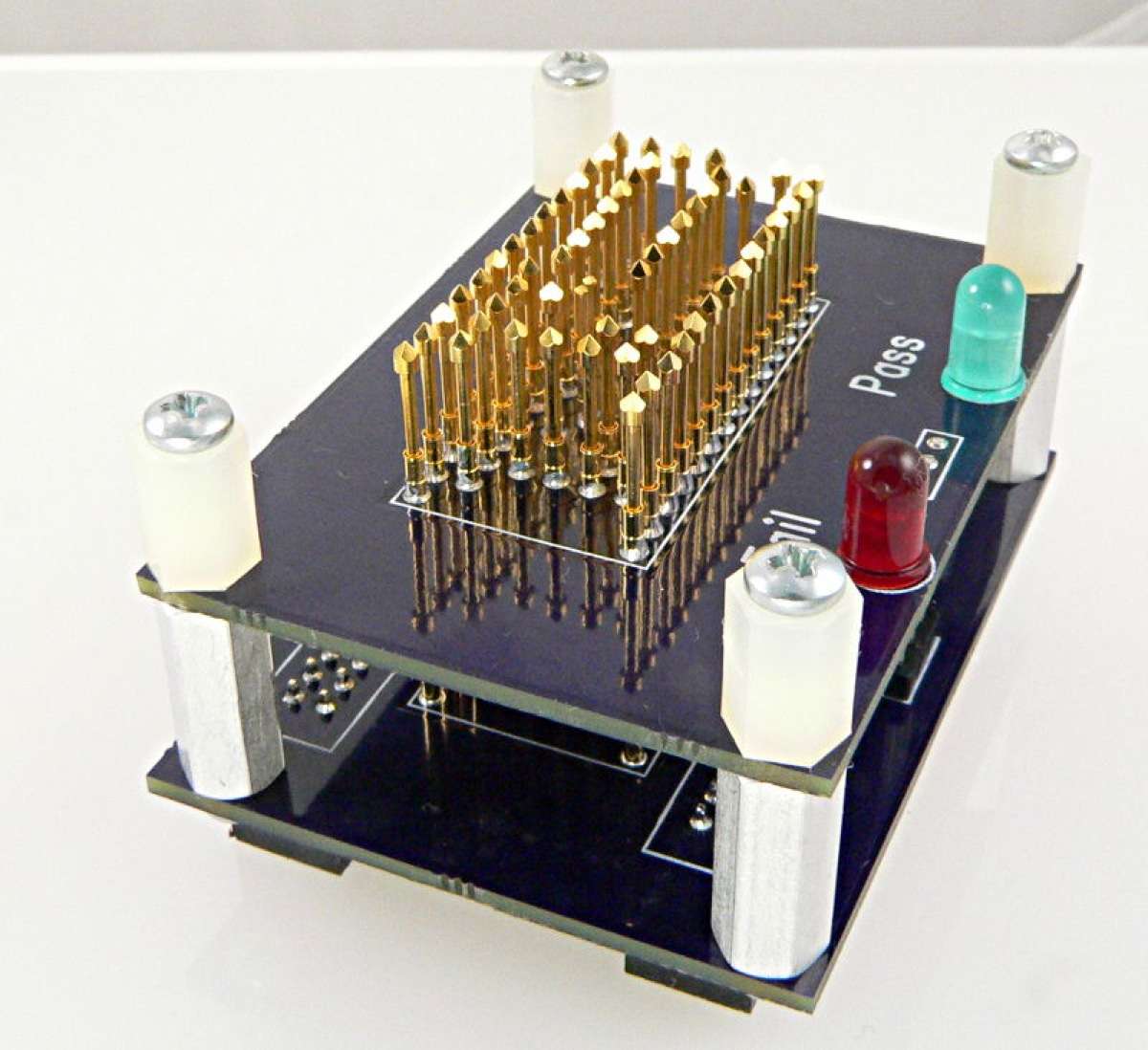

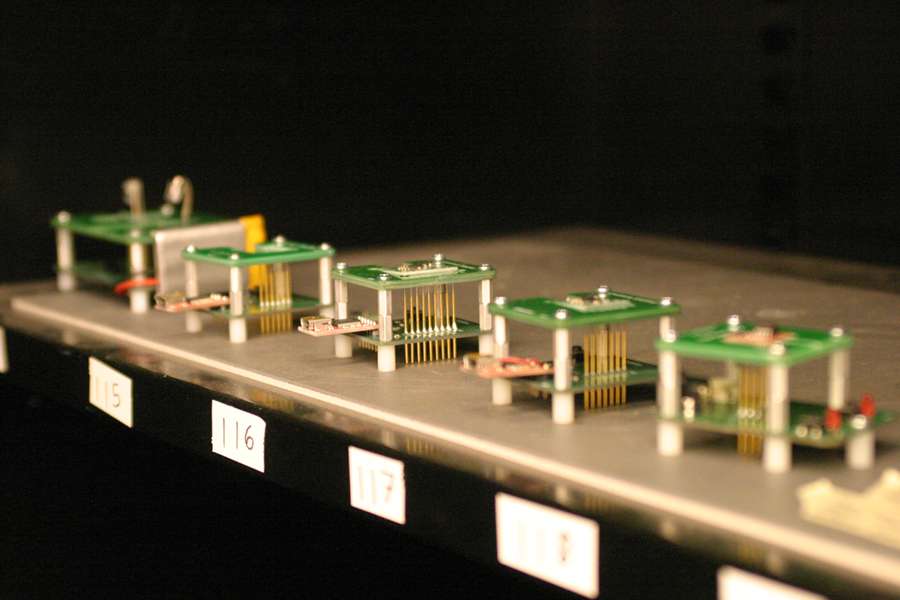

Bed Of Nails Interface Modules

Removable interface modules are the heart of the test fixture. They are responsible for fine alignment of UUT at device loading, provide electrical contact to the bottom side of the UUTs during test, and include custom wiring or an adapter board to route signals to your test interface of choice.

A floating tray on the interface module holds and aligns the UUT in a test-ready position above a bed-of-nails pogo pin array. Linear bearings with coiled springs on the interface module guide the floating plate and UUT onto the pins as the fixture reaches test position. Floating trays on the interface module can also be swapped out if there are changes made to the UUTs during the test process, eliminating the need to purchase entirely new modules for every iteration of a product design.

Bed Of Nails Technique

The bed of nails or universal grid in-circuit testing relies on multiple spring-loaded pogo pins that make contact with several points on the PCB. These pins resemble the bed of nails, hence the name. In the test, each of the pogo pins makes a contact with the circuit node or the point under test. This method can identify, shorts, opens, solder joint bridges, defective components, and other PCB faults.

A typical in-circuit test comprises of multiple pins spread across the board. Applying the multiple pins ensures tens or hundreds of simultaneous connections and tests. Each of these is about 35mm long and usually inserted at the end of a net such as a surface mount pad, a hole, or a test point. With all nets connected, the test takes about 7 seconds.

During the test, the pins introduce some signals and voltages into the circuit after which they measure the resulting values down the line.

Generally, the bed of nails technique is a fast, low-cost test method that is suitable for mass production systems, simple circuits, and analog boards. However, it may be limited when working with complex boards and especially those with small pitch widths, SMDs, BGA and similar components.

Recommended Reading: What Size Roofing Nails For 7 16 Sheathing

Bare Board Test At The Oem

As new PCBs arrive at receiving inspection at the OEM or contract assembler, some testing needs to take place to ensure the PCB meets specifications. Net list testing is too difficult to do at this point so the fabricators results must be accepted. The tests that can be performed at receiving inspection include:

- Impedance testing.

- Verifying that the stackup is correct.

- Measuring the amount of plane capacitance for each power supply voltage.

Impedance testing is performed as described above. Checking the stackup involves using a microscope to examine the stacking stripes added to the edge of the PCB for this purpose. These stacking stripes were discussed in Part 1 of this article.

Measuring the amount of plane capacitance is done with an ordinary capacitance meter connected between Vdd and ground of each supply voltage. It is also useful to add a pair of test contacts that are labeled on the silk screen to make them easy to locate. Again, this is described in detail in Part 1 of this article.

Ict Performs Comprehensive Testing

In circuit testing is traditionally used on mature products, especially in subcontract manufacturing. It uses a bed-of-nails test fixture to access multiple test points on the PCBs bottom side. With sufficient access points, ICT can transmit test signals into and out of PCBs at high speed to perform evaluation of components and circuits.

A bed of nails tester is a traditional electronic test fixture. It has numerous pins inserted into holes, which are aligned using tooling pins to make contact with test points on a printed circuit board and are also connected to a measuring unit by wires. These devices contain an array of small, spring-loaded pogo pins making contact with one node in the circuitry of the device under test .

It takes a few weeks to create the ICT fixture and do its programming. A fixture can either be vacuum or press-down. Vacuum fixtures give better signal reading versus the press-down type. On the other hand, vacuum fixtures are expensive because of their high manufacturing complexity. The bed of nails or in-circuit tester such as 3070 from Agilent is the most common and popular in the contract manufacturing environment.

ICT provides OEM customer such benefits as:

You May Like: How Many Hair Skin And Nails Should I Take

Pcb Assembly Test Software Using Bed Of Nail Fixture

The Printed Circuit Board Assembly which goes into any controller is tested by using bed of nail fixture . This test is used to check PCB manufacturing defects and bad components using the electrical properties . Here, the faults of the test are located directly on the specific components, the device pins, and the network points, and the fault location is accurate, besides, it can greatly improve production efficiency and reduce maintenance costs. The program is under control of automated testing, so the operation is a simple, fast and rapid test.

The test parameters that are measured across different combination of the bed of nail fixture

- AC Voltage

- DC Current

- Resistance

These parameters are compared against the user configurable specification. User has a provision to configure the test sequence and different bed of nail fixture. Test results will be saved into database and test report can be export in PDF file format. User can analyse the test results of different PCB Assembly boards in trend view screen of the test software.

| Software Functions |

|---|

Other Pcb Assembly Testing

There are some other PCB assembly tests in addition to the main ones. These are useful for tuning the manufacturing process to provide a better quality product.

- Peel test: This test measures the strength required to peel off the lamination from the PCB.

- Solder float test: Evaluates the thermal stress on the PCB.

- Solderability tests: This measures how well metal is wetted by solder and ensures surface sturdiness which can increase the chances of forming a solid reliable solder joint. The most common types of Solderability tests is the “Dip and look” method, the surface mount simulation test, wetting balance analysis.

- Micro-sectioning analysis: This analyses the structural characteristics of solder joints, Investigates defects, and anomalies. It can be applied for both surface mounting technology and through-hole technology PCBs.

- PCB contamination testing: This test investigates Corrosion, Degradation, Metallization, and foreign material contamination in the PCB. Which can cause short circuits and other catastrophic failures.

Also Check: How Effective Is Laser Toenail Fungus Removal

Benefits Of Pcba Testing

An inspector holding a PCB after optical inspection

PCBA testing allows us to detect any fatal errors before mass-producing the PCB. It enables companies and manufacturers to save time and money and avoid any brand identity or reputation threat. As such, the sooner manufacturers can detect defects in the PCBA process, the easier and cheaper it will be to rectify them.

What To Test On Pcbs

A PCB consists of several different parts and components. Each of these has an impact on the overall performance of the circuit and the electronics assembly as a whole. Ideally, it is important to test everything. This includes, but not limited to verifying the

- Electrical conductivity

- Component placement, alignment, polarity, orientation, etc.

Also Check: How To Keep Your Nails Healthy And Strong

Notes And Details About The In Circuit Test Fixtures

Automatic Test Equipment, ATE Includes:See also: ATE basics PCB inspection techniques Functional test, FATE Developing test strategy

The term bed of nails is a rather graphic description of what many fixtures look like, having a large number of test points or probes proud of a board that holds them in place.

Although the concept of the in-circuit test fixture or bed of nails is broadly the same whatever manufacturer is used, there are a number of variations on the basic theme.

Ict Failures & Mechanical Simulation

Bed-of-nails testing has been known to cause mechanical failures such as capacitor flex cracking and pad cratering. This typically occurs if there is excessive board flexure due to poor support placement or high probe forces. It can be challenging to optimize for ideal support locations and probe forces without spending resources designing and building an ICT fixture. Current methods typically employ strain gaging or similar techniques to monitor board flexure. More recently, some have looked at finite element simulation to proactively design or adjust an ICT fixture to avoid these mechanical failure modes. This approach can be implemented as part of a design for manufacturability methodology to provide rapid feedback on ICT design and reduce costs.

You May Like: How To Soak Off Acrylic Nails At Home

Getting The Edge On Design For Test

Building a Printed Circuit Board that works as intended is only has hard as you make it as a designer. The truth is that the layout can be a source of success or failure. Most of the features in the CAD software are geared towards avoiding failure. Going above acceptable and gearing up for success in the face of a competitive market is a value add that a test-minded PCB Designer can deliver.

In Circuit Test Fixture Basics

The In-circuit test fixture is required to interface the main tester with the particular board under test. It will have a main connector that interfaces to the tester and wires that are taken from the connector to individual pins / probes / or “nails” that make contact with the required nodes on the board under test.

The probes are held in place by what may be termed a base-board. This is precision drilled to ensure that the probes are held in exactly the right place for the fixture to make contact with the required nodes on the board.

The board is held in place accurately by the fixture and pulled onto spring loaded pins that make contact with connections on the board. The board may either be pulled down under the action of a vacuum or it may be achieved mechanically.

Typically pins are placed on a 0.1 inch matrix. Many new surface mount IC packages require a much finer pitch, and to achieve this an adapter is often used.

There are about three main methods for pulling the board onto the probes:

Don’t Miss: How Much Is Clear Nails Plus

Design Manual Test Press Fixtures To Your Needs

Our manual test press fixtures are developed to be fully integrated test solutions that are ready for use as soon as they are received. You wont face Some assembly required or batteries not included when working with RTI to develop a test press solution.

Test presses consist of a standalone base that is sized to your application and a removable interface module that manages all electrical interconnects incorporated into the working solution and aligns the unit under test to the test points.

High Quality Fixture Kits

You can be sure that our all of our test fixtures are built to a high standard. Our partnership with the Everett Charles Technologies Test Fixture Group, the worlds leading manufacturer of PCB test fixtures, allows us to offer a best in class range of test fixture kits and customisation. And our longstanding experience in the field guarantees you a professional and knowledgeable service.

Also Check: How To Get Gel Nails

Order Pcb Assembly Going Through Testings Before Delivery

If you ask a PCB manufacturer to assemble your boards, you must want to get boards that were already been tested before going to your hand. Otherwise, you will have to test them, which is fussy and cozy. Here is a good choice to have your PCBs made, assembled, and tested at once – working withPCBONLINE. This is a one-stop PCB company that is good at advanced circuit boards. You can have them make, assemble, and even design advanced PCBs, and they test your PCB carefully before delivering it to you.

PCBONLINE ensures PCB quality by precise PCBA testing:

- SPI, x-ray testing, AOI, functional testing, and aging testing are conducted default free of charge.

- You can require any other PCBA testings from us, like flying probe test, boundary scan, peel test, solder float test, solderability test, micro-sectioning analysis, PCB contamination testing.

- Our experienced engineers can design a build-in-self test system to help you repair easily.

- We check your Gerber and BOM carefully before PCB manufacturing and assembly, which reduces possible risk.

- We offer free PCB/PCBA samples for batch production.

Most Popular Pcba Testing Methods

The most popular PCBA testing procedures are:

An operator visually inspects a PCB assembly.

This technique involves an experienced technician manually inspecting the PCB through their naked eyes or magnifiers. It’s’ cheap, and we can easily find most PCB soldering problems using this method. However, detection largely depends on the technician’s skill. Additionally, you can only inspect visible solder joints. Thus, it may be more suitable for smaller productions with simple PCBA designs.

Read Also: Which Is Better Gel Or Acrylic Nails

Pcba Test: A Comprehensive Guide

Circuit tests are an integral part of the PCB assembly process. Running functional tests can help manufacturers ensure product quality and prevent a wide range of manufacturing defects. However, they need to understand what PCBA test they have at their disposal. Thus, the following guide will explore the intricacies of PCBA testing and why it’s’ so important. But first, let’s explore what a PCBA test is.

Hardware circuit testing

The PCBA process involves operating a set of disparate and complex equipment. If there is an error in any equipment or how workers use it, it may fault the final product. Some of these faults are easy to detect, while others are more subtle. Thus, we require different techniques to detect these faults. Some of the most common PCBA tests include in-circuit tests , functional circuit tests , burn-in tests, and fatigue tests.

Bed Of Nails Fixture Test

Bed of nails fixture test, also called a calm shell or universal grid, is implemented through dozens of stiff testing fixtures just like what its name is described.

Fixtures with springs are connected to each test point on each circuit board. Springs are capable of equipping each test point with pressure of 100g to 200g to ensure excellent contact of test points. Such fixtures that are arranged in a matrix manifest themselves as a bed of nails. Controlled by test software, programming should be carried out on test points and test signals, through which testers are allowed to obtain information concerning all test points. To implement this test, fixtures will be selected and assembled according to distribution and positions of test nodes or points on a board.

Recommended Reading: How To Clean Nail Polish From Carpet